- What the industry shows

- Again, what is a warehouse management system in relation to its functions?

- Ways to capitalize on these WMS functions. What to choose?

- Why choose bespoke options to obtain the best warehouse management system features?

- Warehouse management system functions that we regularly deliver

- Why opt for cooperating with Andersen?

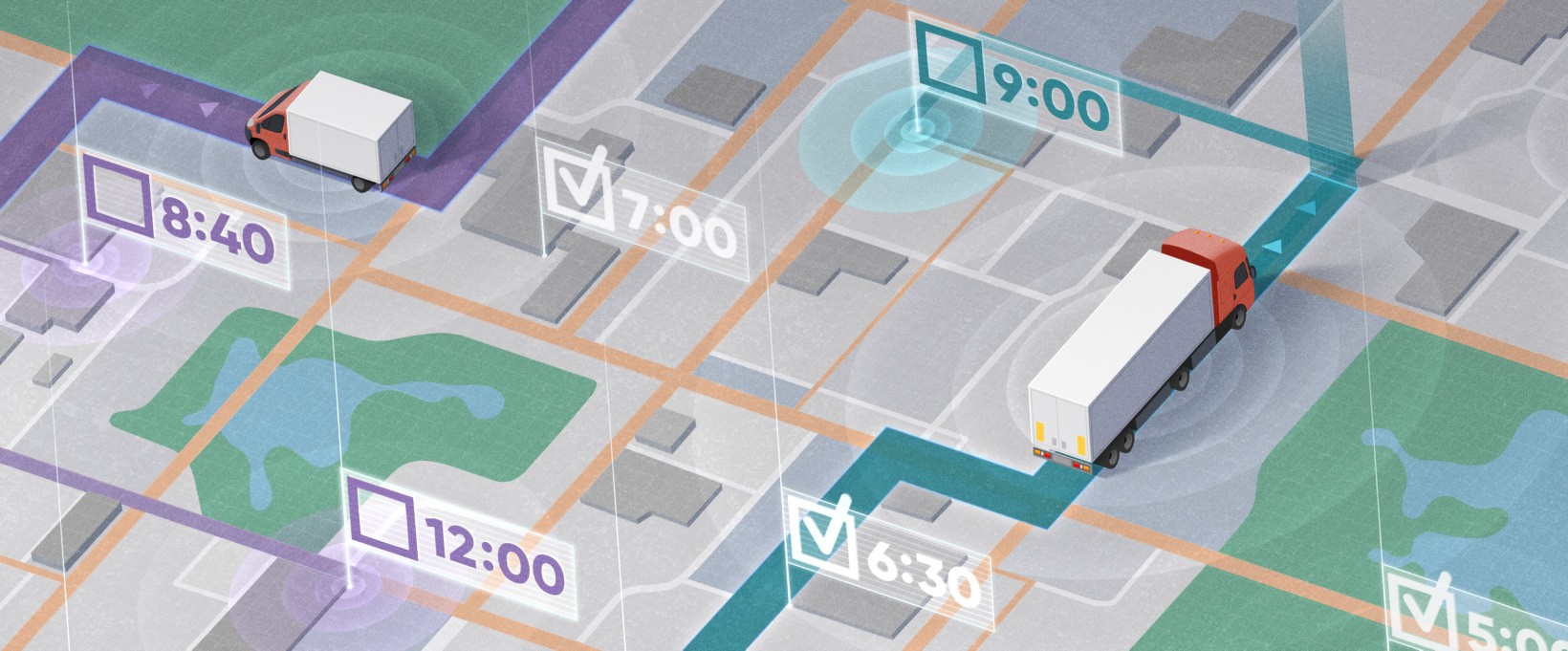

To initiate a well-balanced and productive discussion, we at Andersen normally begin with definitions and illustrative figures. What is a warehouse management system that matches modern expectations and criteria? Our team would propose the following perspective: warehouse management system functions are all about facilitating the cost-effective and transparent tracking of day-to-day operations in a warehouse, as well as controlling them.

Sounds simple, yet easier said than done. Flows of goods, warehouses, the scale of transportation internally and externally — all these are enormous. Unless a proper set of warehouse management functions are in place, the needed volumes, speed, intensity, and precision levels will inevitably result in:

- Incorrect inventory records;

- Inadequate space allocation;

- Flawed staff management;

- Challenges concerning seasonal warehousing;

- Adherence to rudimentary practices;

- Poor-quality picking methods and inadequate order management.

All these observations are based on real-life issues we at Andersen have already resolved on numerous occasions, in the capacity of a warehouse management system development hub.

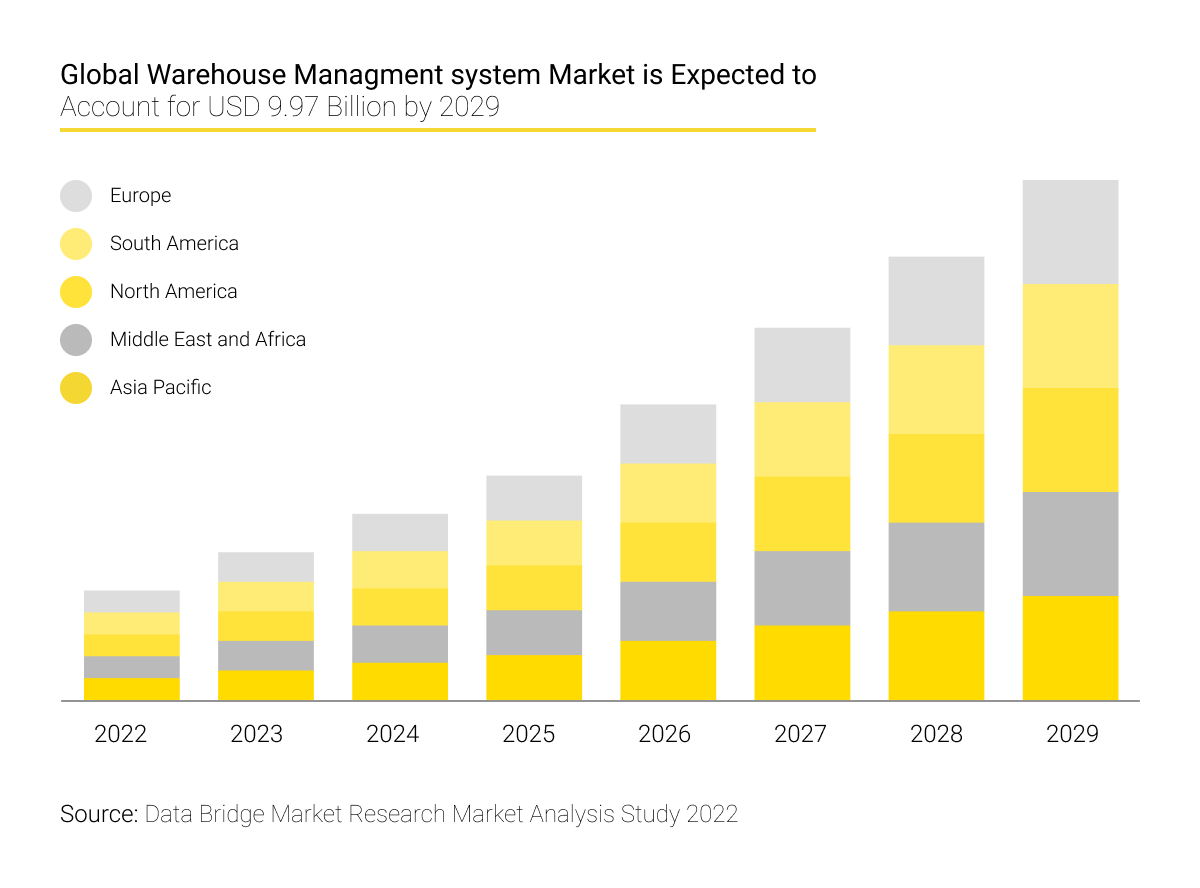

As the following figures say, these problems are faced by many.

Interesting fact: Businesses correctly view warehousing automation as the key problem-solver for their industry-specific woes, including those mentioned above. That is, they seek to optimize and streamline repetitive and time-consuming tasks typically carried out manually by workers.

As the state of the industry indicates, the automation wave is on the rise. In 2023, the worldwide warehouse automation market surpassed a valuation of $23 billion. Projections indicate an impressive CAGR of approximately 15% in the near future, with expectations to expand to $41 billion by 2027.

Unsurprisingly, the lion’s share of that growth belongs to the developed economies. From a global standpoint, significant automation remains absent in over 80% of warehouses worldwide, indicating a remarkable untapped potential for modernization in their operations.

What the industry shows

As figures show, the role of warehouse management systems has been growing steadily over the years. Back in 2016, the size of the WMS market, globally, was roughly $1.4 billion. Around 2022, it exceeded $3 billion. These growth rates indicate that market players and their clients are both interested in investing in ever-more sophisticated and advanced functions.

Indeed, as Supply Chain Management Review cited a year ago (based on ‘Materials Handling Technology Study’):

- 56% of companies surveyed had already integrated warehouse management systems into their business activities;

- 32% of companies were planning to either assess, procure, or enhance their respective software solutions, with a notable portion opting to invest in WMS.

They do so for a reason.

Did you know: Back in 2020, the global count of warehouses stood at around 150,000, with 25K+ of them situated in North America. With the ongoing surge in eCommerce business activities (which is not going to cease), projections indicate that the global warehouse count will approach nearly 180,000 by 2025.

Again, what is a warehouse management system in relation to its functions?

In a nutshell, the mission of any WMS is facilitating seamless connections between your warehouse, equipment, staff members, and stock. Doing so secures instant visibility of the entire workflow. Generally, such WMS features encompass:

- Barcode/RFID support;

- Layout and slotting;

- Tracking and managing inventory levels, locations, and movements;

- Workforce and task allocation, supervision, and monitoring that embrace receiving, picking, packing, putaway, and shipping;

- Auditing;

- Reporting and analytics (to dive more deeply into this particular aspect, pay attention to this overview of business intelligence in supply chain management).

Did you know: The aforementioned 150,000 warehouses in existence back in 2020 occupied around 2.3 billion square meters in total (which is 25 billion square feet in the Imperial system).

Ways to capitalize on these WMS functions. What to choose?

As a custom software vendor, we value systematic thinking. Succeeding in business requires the capability to recognize the uniqueness of each situation within the broader context of the overall landscape. This focus on minor details in broader major contexts is, among other things, visible in this piece dedicated to various types of logistics management software.

So, what we intend to do here is follow the same pattern and offer this classification of available options:

- What to choose #1. Simple standalone WMS

These offer limited functions and do not mandate intricate integrations or complete interconnectedness. Consequently, firms frequently use them for limited-scope tasks such as inventory tracking and control.

If your entity is small and a standalone option is able to deal with inventory properly, it is acceptable to limit yourself to this. However, bear in mind that incorrect product packaging and delivery errors contribute to 17% of inventory inaccuracies, bringing about customer loss.

- What to choose #2. Cloud WMS

This class of software is delivered in the form of SaaS, granting one prompt and effortless access to a predefined set of features, including analytics and BI capacities.

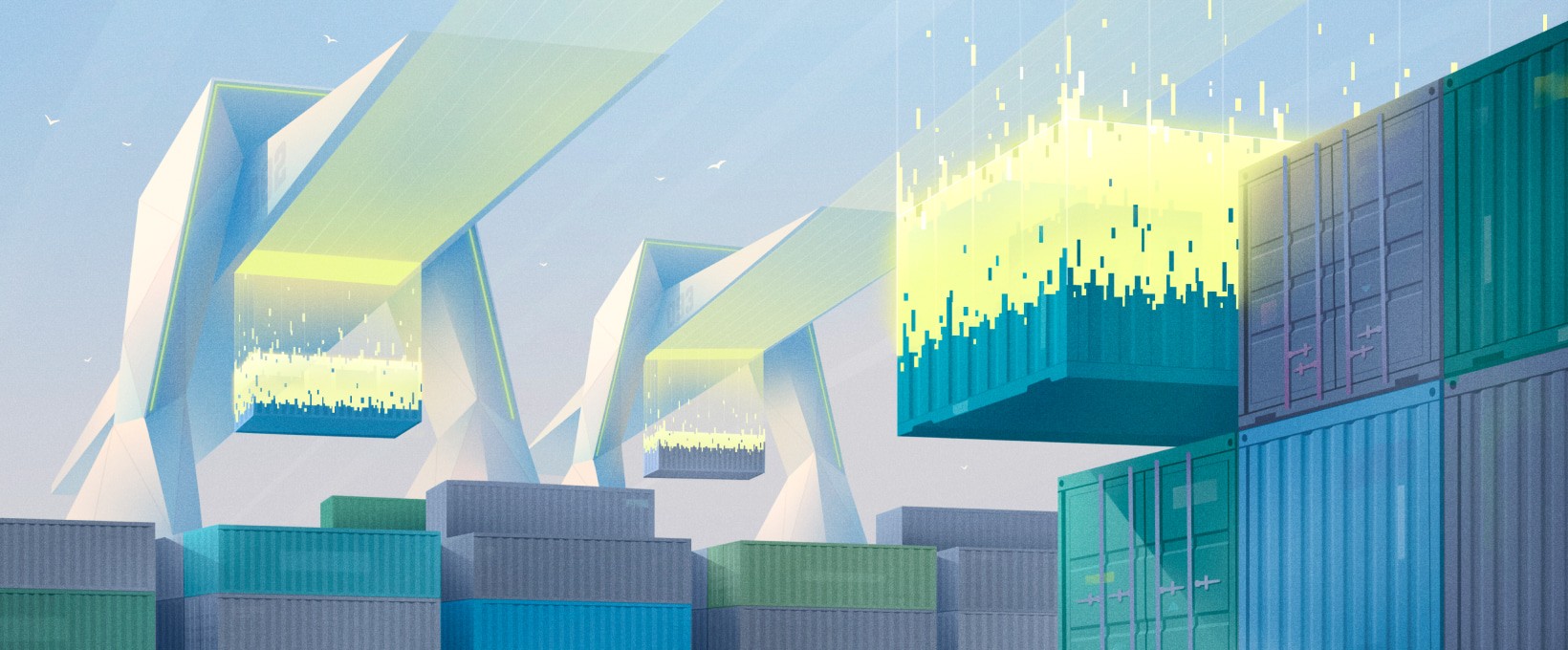

- What to choose #3. Custom WMS with ERP

Incorporating an enterprise resource planning (ERP) module into your system boosts its functionalities with up-to-date features, including but not limited to workforce management, client communication, financial operations, and marketing and sales endeavors.

- What to choose #4. Custom WMS with supply chain modules

This alternative integrates such facets as warehousing, transportation, distribution, and production. It monitors the procurement and replenishment of items, production cycles, partnerships, etc.

Whatever your eventual choice might be, remember an important figure.

The primary underlying cause of costly inventory fulfillment issues, as reported by 62% of respondents, was human error stemming from manually executed professional activities.

Make sure your pick is actually capable of preventing human-caused occurrences of that or similar types (or at least effective in dealing with their consequences).

Why choose bespoke options to obtain the best warehouse management system features?

Being Andersen’s team, we would advocate for custom software. However, we do admit that there are both pros and cons to consider here, just like in any business case.

What we are going to do is to start with disadvantages.

Cons of bespoke systems. What to consider:

-

Elevated expenses. The greater the need for innovative and unique modules in your warehouse management system, the higher the investment volume to anticipate;

-

Significant time required for deployment. While an off-the-shelf system can be swiftly implemented, developing a well-thought-out bespoke product is a time-consuming endeavor;

-

Involvement of your team. Collaborating with the vendor alongside your in-house experts, throughout all the project stages, is crucial to ensure an accurate understanding of your intentions regarding the eventual system. Thus, be ready to get a little distracted from your core activities from time to time.

Pros of bespoke systems. What to consider:

-

Tailored systems with compelling returns on investment. Acquire a robust tool capable of addressing all your challenges effectively, streamlining daily operations, and preserving valuable resources;

-

Mitigated security risks. Off-the-shelf systems are essentially a black box, offering no assurances regarding code quality. With custom engineering, you have the flexibility to implement as many security measures as necessary;

-

Comprehensive support. Count on prompt, high-quality support coordinated by dedicated managers;

-

Seamless integration with your tech ecosystem. Many companies utilize a variety of technologies to manage logistics, staffing, compliance, and more. Opting for a bespoke system ensures seamless harmony from this point of view.

Now let’s discuss what the warehouse management system features we could give you are.

Interesting fact: a noteworthy majority, 77% of organizations, feel determined to implement automated warehouse systems and strategize to optimize performance via data-driven approaches.

Warehouse management system functions that we regularly deliver

What is WMS when it comes to its functions? As a rule, our customers’ expectations include:

What functions to search for in a warehouse management system #1? Procurement and purchase order generation. This feature enables end-users to conveniently look through the data provided by their suppliers and swiftly place orders for the needed items.

What functions to explore in a warehouse management system #2? The receiving and putaway capabilities. These empower end-users to scan purchased goods and place them in the most optimal spots across their storage facilities.

What functions to look for in a warehouse management system #3? Storing and stock control. Organizations rely on this feature to keep track of their items.

What functions to resort to in a warehouse management system #4? Sales order generation. Via this, entities can manage their sales from any device with convenience, availing themselves of automatically generated invoices.

What function to rely on in a warehouse management system #5? Picking and packing. Businesses can rapidly search for, select, pack, and ship orders in an economical fashion.

What functions to request in a warehouse management system #6? Personnel administration. This covers scheduling, employee reporting, and safety control, allowing firms to assign people, track their efficiency, evaluate performance, build labor cost projections, and abide by labor law guidelines.

What functions to order in a warehouse management system #7? Accounting. Finance divisions can set customizable metrics, draw up graphs, charts, and projections, compile reports, balance sheets, etc.

When people think of the warehousing business, they tend to visualize buildings, spaces, and equipment.

At the same time, those familiar with business mainly think and complain about HR issues, as those are the staffing challenges that often cause the main headache. Some facts to prove this point:

In America, labor fluctuations that should be properly tackled look obvious. For instance, per a survey conducted by ARC Advisory Group, 35% of warehouses experience a seasonal increase in their workforce of more than 20%. Additionally, 8% of them see a surge of over 100% in their employee numbers during peak seasons;

As per a study by Logistics Management, 73% of warehouse operators are currently facing difficulties in finding an adequate number of workers. This challenge is expected to intensify in the upcoming years, with projections indicating a staggering 85 million unfilled jobs globally by 2030. So one has to resort to a mix of greater automation and effective management of human workers.

Why opt for cooperating with Andersen?

How do you go about selecting a reliable vendor that is really able to provide you with cutting-edge WMS functions?

We will attempt to illustrate the selection criteria by expanding upon Andersen’s ability to deliver state-of-the-art warehouse management system functions:

-

What is the vendor's overall rating based on client reviews and assessments? In our case, we take pride in a 4.9 rating on Clutch. This reflects, inter alia, our full preparedness to work on the latest functions;

-

Does the company have an adequate number of staff with relevant industry experience? Andersen employs over 320 domain-focused IT experts with extensive knowledge in supply chains, logistics, and warehousing functions;

-

Does the company have a robust portfolio? Andersen showcases a portfolio of over 290 successfully completed software projects in the Logistics field, including those with warehousing functions.

Based on the details and facts mentioned earlier, it's reasonable to conclude that a tailored-fit WMS would be the optimal choice for your company, especially if your operations are complex. With us, you will obtain the very functions needed to conduct business.

Our team is enthusiastic about leveraging our expertise to craft such a tool for you. Take the initial step towards launching your IT initiative by reaching out to us!

To wrap up, what is a warehouse management system if you entrust us with its creation? Exactly what you want it to be.